The role of compression

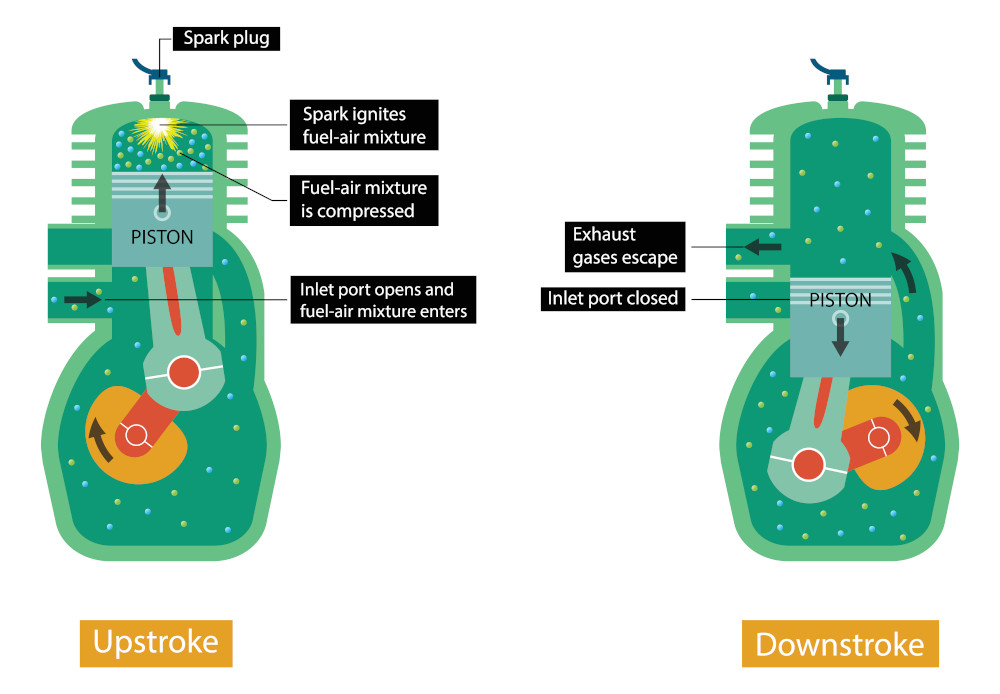

Good compression is an essential component for any engine to run properly. To understand how compression works in an engine, let’s break down the basics. Firstly, your engine is a pressurized system. Inside this system, a mixture of fuel and air is combusted using that pressure. This combustion process creates the force that rotates the crankshaft, which in turn powers external parts like the head on your trimmer.

Signs of lost compression include decreased power or difficulty starting. But don’t worry, diagnosing the cause of compression loss is the first step to fixing the problem.

Common causes of low compression

Worn or damaged piston rings

Piston rings extend or push outward against the cylinder walls, resulting in a vacuum seal. This vacuum seal prevents the air and fuel mixer from escaping. These rings also expand when the piston becomes hot, therefore reducing blowby (escape of air-fuel mixture). Over time a ring may break, become fused, or be damaged, consequently degrading the effectiveness of the vacuum.

Loose or damaged parts

Low compression can sometimes be caused by loose or damaged engine parts. Engines constantly vibrate, which can loosen bolts and other components over time. During routine maintenance, it’s important to inspect for cracks in the engine block, worn gaskets, loose bolts, and worn spark plugs. Excessive oil buildup on the engine’s external surfaces can be a good indicator of a damaged gasket or crack.

Scored piston

A damaged or scored piston will have visible vertical lines or indentations. These imperfections allow the air-fuel mixture to leak, reducing compression. A healthy piston, in contrast, will be smooth and free of any major indentations. Pistons can become damaged for several reasons, including using the wrong fuel mixture, accidentally running on straight gas, or simply due to normal wear and tear over time.

Removing the spark plug, muffler, or carburetor (depending on your engine) can provide visual access to the piston. The extent of the damage will determine the repair approach. In some cases, a simple replacement of the piston rings might restore compression. However, if the piston itself is damaged, there’s a good chance the cylinder wall is also compromised. In this scenario, a complete rebuild of the top end would be necessary.

Diagnosing low compression

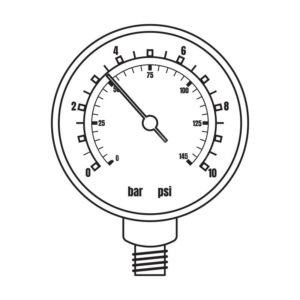

A compression tester is one of the most common ways to measure your engine’s PSI (pound per square inch). First, remove the spark plug and install the compression adapter into the spark plug hole. Place the engine in the run position and pull the starter recoil until the compression gauge needle reaches the highest PSI number on the gauge.

Most engines need a PSI of 90 and above to function properly, however, some engines have been known to run at lesser PSI. They are many compression testers on the market, so be sure to shop around for a high-quality set. Alternatively, some auto stores will loan or rent out their compression testers.

Another method of testing is, comparing an engine suspected of low compression with a functioning engine. The starter chord on an engine with low compression will require less force to pull when compared to a functioning engine.

By understanding the importance of compression and the signs of its decline, you can keep your engine running smoothly.If you suspect compression loss, don’t hesitate to diagnose the issue! A compression tester can be a valuable tool in this process. You can find a reliable compression tester at most automotive store or online to help you identify the problem and get your engine back in top shape. Remember, early detection is key to preventing further damage and keeping your equipment running for years to come.