A Carburetor is like the heart of a small engine. These devices combine the right amount of gas and air mixture needed for internal combustion. If either one is not circulating in the right amount, then an engine may not run properly or start. You will have to adjust the carburetor if this is the case.

Step 1

Put on proper Personal protective equipment (PPE). Place weed whacker on flat ground or workbench.

Step 2

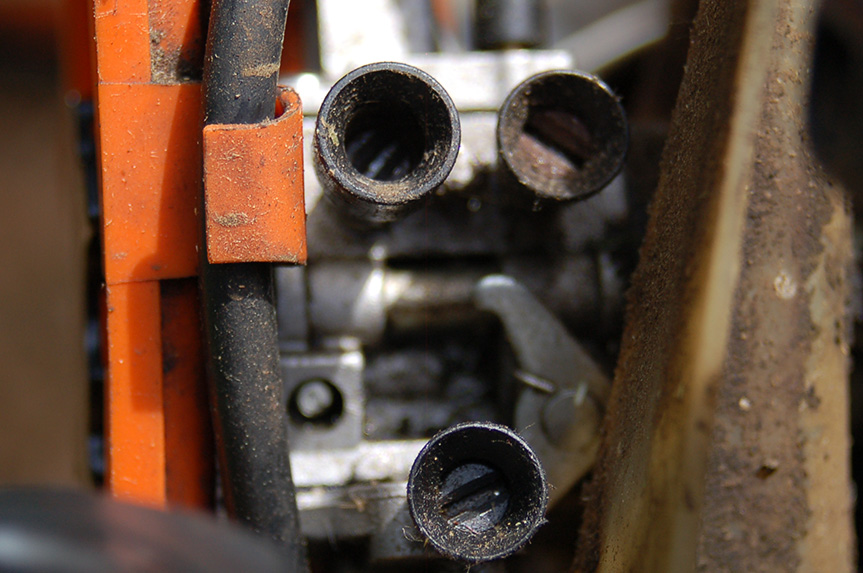

Unscrew and remove the top engine cover shroud. Removing the cover will give you a better view of the FS200 carburetor.

Step 3

Using a flat-head screwdriver turn the H screw located on the top right counter-clockwise all the way until it stops. Depending on the type of carburetor the screw may not stop. In this case, turn it while being careful not to let it fall out.

Step 4

Turn the L screw clockwise all the way in or until it stops. Next, turn the L screw counterclockwise one turn to open it.

Step 5

Prime and begin the starting sequence for your engine. Allow your engine to warm up for about a minute or two. If the cutting heads start to move to turn the H screw clockwise until the head stops moving, then a half-turn counterclockwise again.

Step 6

Squeeze the throttle trigger all the way in order to rev up the engine. Adjust the H screw until the engine runs without sputtering.

step 7 (optional)

Turn the engine off and on back again. If the engine stops while idling you Turn the LA screw slowly clockwise until the engine runs smoothly.

The goal of adjusting is to get the engine to run as smoothly as possible, so you will have to fine-tune it according to your needs. Alternatively, you can purchase a stihl fs200 carburetor kit online.